Troubleshooting Receptacles

Troubleshooting receptacles with no power is our number one troubleshooting call, year over year. In many cases, the final diagnosis turns out to be a fault with one of the receptacles on the circuit, affecting all the receptacles on that line.

Was the receptacle faulty on purchase? As with nearly every product and service on the market today, there is a range of quality available to choose from.

When troubleshooting receptacles, we find that the quality of the product as well as the quality of the installation are often both to blame.

Receptacle Quality

The quality of the receptacle always plays a role. There are cheap-to-buy, low quality products available that still have CSA or ULc certification. What makes them cheaper is that they are made of inferior plastics and parts. The plastic can be poor quality, made from recycled garbage bags, and food containers. These plastics become brittle and crack over time. The insides of a receptacle have similar pitfalls in manufacturing. A company with quality products will be using new and quality controlled resins for the plastic portion of their receptacles and high quality metal parts inside.

Troubleshooting Receptacles – Quality of Receptacle Installation- Backstabbing

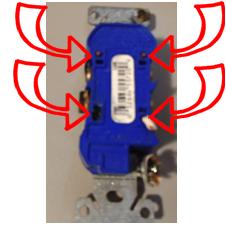

The quality of the installation is the next big pitfall. Most receptacles are designed to have two methods of connection. One the “old fashioned way” wrapping the wire around the little screws on the side, and the other where you just shove the wire into tiny holes on the back of the receptacle. Both are acceptable, but the second way is notably inferior.

The trade term is back-stabbing. It is used by both amateurs and sometimes pro’s who rely on speed to make their profit (often used for new subdivision wiring). This practice is snubbed by professionals who know that a more secure connection point will serve the client far better over the long run.

Receptacles designed for backstabbing have small barbs or tension springs to hold the wire in to place once inserted. The only point of contact between wire and outlet is miniscule (less than 1/16th”) and is prone to overheating under anything other than the most minor of electrical loads.

Back in the late ’60’s and early ’70’s there were several cheap outlets produced that only had “back-stabbed” connection points. When troubleshooting receptacles like these, we see them in combination with aluminum wiring. These were directly responsible for major fires before they lost certification.

Best Practice for Installing a Receptacle

A properly bent wire (shepherd’s hook) threaded around the screw post in the right direction, and tightened properly provides a large, visibly inspected and tight connection for the electricity to flow through the receptacle. When you consider the small amount of time it takes to make a proper connection, compared to the length of time the receptacle should work (approximately 20 years) using the best techniques is sound judgement.

When looking for a professional installation of receptacles, you can rely on The Shock Doctors.